BSK Associates Expands Presence with Opening of South Bay Area Office in San Jose

BSK Associates Expands Presence with Opening of South Bay Area Office in San Jose

BSK Associates, a leading engineering and analytical consulting firm, proudly announces the grand opening of its newest location, the South Bay Area Office, situated at 2510 Seaboard Avenue, San Jose, CA 95131. This strategic expansion underscores BSK’s commitment to better serve clients and employees while reinforcing its influential presence in the region.

BSK Associates has been a strong force in the South Bay Area for several years, and the opening of the new office reflects the company’s dedication to enhancing local services. BSK, known for its dynamic community of engineers, scientists, and construction professionals, sees the South Bay Area as a pivotal hub for infrastructure development, making it an ideal location for the company’s continued growth.

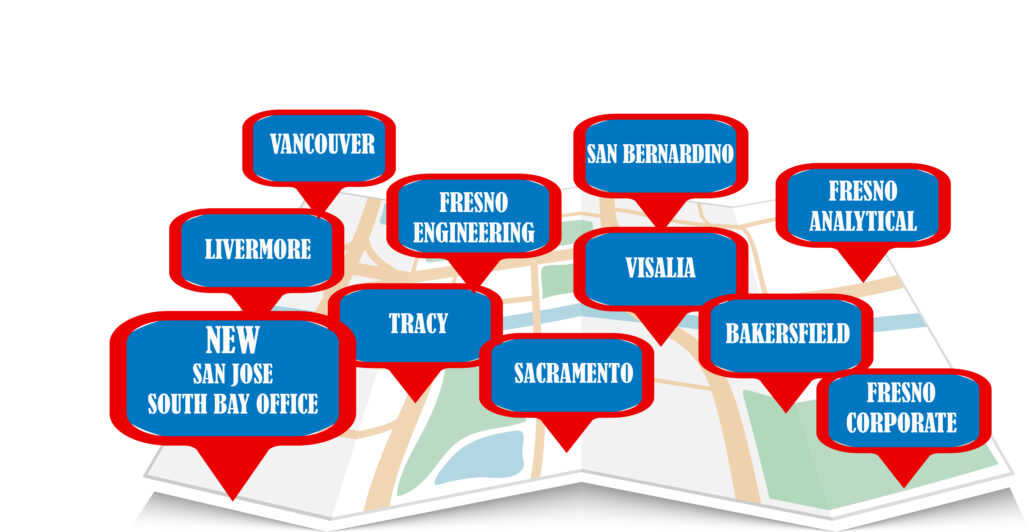

Over the past four years, BSK has experienced remarkable expansion, marked by the establishment of four new offices. This growth is highlighted by the grand opening of two new Fresno locations for both our corporate office and analytical laboratory. Additionally, two new service center hubs have been opened in Visalia and Tracy. The company’s success is attributed to its unwavering commitment to excellence and the diverse range of services it offers, including engineering, analytical consulting, construction management, construction materials inspection and testing, and environmental professional services.

“The decision to open the South Bay Area Office has been a long-standing vision, we want to leverage the firm’s quality services against the numerous opportunities available in the region.” Said Cristiano Melo, Livermore Branch Manager at BSK Associates.

BSK Associates has actively pursued on-call contracts in the South Bay, including collaborations with Santa Clara County, the Town of Los Gatos, and the Santa Clara Valley Transportation Authority, along with various project-specific contracts. The establishment of the South Bay Area Office will allow BSK to fulfill the requirements of these contracts, ensuring a local presence, reduced travel charges, and quicker response times.

“We are excited to announce the opening of our South Bay Area Office in San Jose. This expansion represents a significant milestone for BSK Associates, enabling us to better serve our clients and strengthen our ties within the vibrant engineering and construction community of the South Bay Area,” said Tim Rodriguez, Chief Operating Officer at BSK Associates.

BSK Associates, an Employee Stock Ownership Plan (ESOP) company, is deeply committed to community engagement and believes in giving back to the communities we serve. We recognize the direct link between community well-being and the success of BSK and its employees. Our community involvement goals focus on making the most positive impact through personal, office, and firm-sponsored activities. As an ESOP, we empower our employees to continue making a difference in their communities.

With a firm foundation built on growth and a commitment to delivering high-quality services, BSK Associates looks forward to making a positive impact in the South Bay Area.

For further information, please contact us.

Like, Follow, Share

BSK strongly believes in giving back to the communities in which we work. We make sure our community involvement goals have a positive impact on the communities which we serve; because, in the end it’s all about community.

Like us on Facebook. Also, follow us on LinkedIn and Twitter. Additionally, explore some of our projects here!

Have a question about the services we offer? Check out our webpage @bskassociates.com.

Don’t forget to check out our opportunities page! You too can work for an amazing ESOP organization!!!